Optimizing Resource Allocation in Industry

Effective resource allocation is a cornerstone of success for businesses across various sectors. In today's dynamic global landscape, industries are continually seeking methods to enhance their operational efficiency, reduce waste, and maximize output from available resources. This involves a strategic approach to managing everything from raw materials and energy to human capital and technological infrastructure, ensuring every component contributes optimally to the overarching goals of the enterprise.

In an increasingly competitive global market, the ability to effectively manage and deploy resources can distinguish successful enterprises from those that struggle. Optimizing resource allocation involves a deliberate and continuous process of evaluating needs, identifying available assets, and strategically assigning them to achieve specific objectives. This practice is vital for maintaining profitability, fostering innovation, and ensuring long-term sustainability across various industrial applications.

Enhancing Efficiency in Operations and Production

Operational efficiency and robust production processes are central to industrial success. This involves streamlining workflows, minimizing bottlenecks, and ensuring that machinery and personnel are utilized to their full potential. By regularly analyzing production data, businesses can identify areas for improvement, implement lean manufacturing principles, and adopt new methodologies that reduce waste and improve output quality. The goal is to produce more with less, without compromising standards or employee well-being.

Strategic Workforce Management and Technology Integration

The workforce is a critical resource, and its effective management is paramount. This includes recruiting skilled individuals, providing ongoing training, and fostering an environment that promotes productivity and innovation. Integrating advanced technology, such as enterprise resource planning (ERP) systems and industrial internet of things (IIoT) devices, can significantly enhance workforce capabilities by automating routine tasks, improving data accuracy, and providing real-time insights for decision-making. Strategic technology adoption can also empower employees with better tools, leading to increased efficiency and job satisfaction.

Supply Chain and Logistics Optimization

Efficient supply chain management and optimized logistics are crucial for timely delivery and cost control. This involves careful planning, procurement, and distribution of materials and finished products. Businesses are increasingly leveraging digital tools for inventory management, demand forecasting, and route optimization to reduce lead times, minimize carrying costs, and mitigate risks associated with supply disruptions. A well-managed supply chain ensures that resources are available when and where they are needed, supporting uninterrupted production and customer satisfaction.

Driving Innovation and Sustainable Growth

Innovation is a key driver of long-term growth and competitive advantage. Allocating resources to research and development, as well as fostering a culture of continuous improvement, allows enterprises to adapt to changing market demands and develop new products or services. Furthermore, integrating sustainability practices into resource allocation decisions, such as investing in renewable energy or implementing waste reduction programs, not only aligns with environmental responsibility but can also lead to cost savings and enhanced brand reputation. This strategic approach supports both economic viability and ecological stewardship.

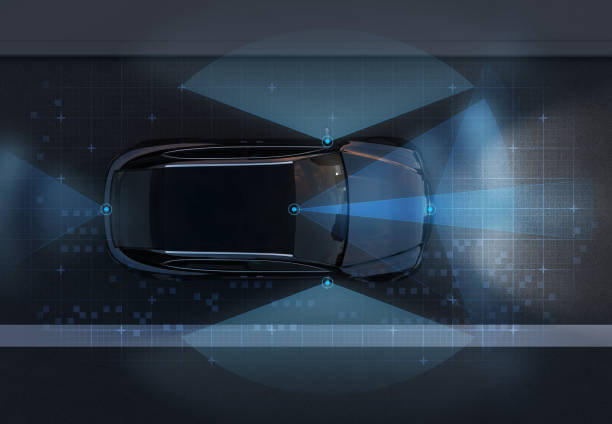

Digital Transformation and Automation in Enterprise

Digital transformation and automation are reshaping industrial operations. Investing in digital technologies, from artificial intelligence and machine learning to robotics and cloud computing, allows businesses to optimize complex processes, enhance data analysis capabilities, and improve decision-making. Automation can increase precision, speed, and safety in manufacturing, while digital platforms facilitate better communication and collaboration across departments and global locations. This shift enables enterprises to become more agile, responsive, and resilient in an evolving industrial landscape, driving significant improvements in overall resource utilization.

Optimizing resource allocation is an ongoing journey that requires continuous assessment, strategic planning, and adaptive execution. By focusing on efficiency, embracing technological advancements, and prioritizing sustainable practices, industries can achieve greater productivity, foster innovation, and secure a stronger position in the global economy. This holistic approach ensures that every resource, from human capital to raw materials and technological infrastructure, contributes maximally to an organization’s objectives.