Predictive maintenance for automotive longevity

Predictive maintenance represents a significant advancement in how vehicles are cared for, moving beyond traditional scheduled or reactive repair methods. By leveraging data and advanced analytics, this approach aims to foresee potential component failures before they occur, allowing for timely interventions. This proactive strategy is designed to extend the operational life of automotive assets, enhance safety, and optimize overall performance for drivers and fleet operators alike.

Integrating Technology for Automotive Insight

Modern automotive systems generate vast amounts of data, which forms the foundation of predictive maintenance. This process involves deploying sensors throughout a vehicle to monitor key parameters such as engine temperature, fluid levels, tire pressure, vibration patterns, and component wear. Advanced technology, including artificial intelligence and machine learning algorithms, then analyzes this continuous stream of data to identify subtle anomalies or trends that could indicate an impending failure. This innovation allows for a shift from reactive repairs to proactive care, enabling maintenance actions to be scheduled precisely when needed, rather than at fixed intervals or after a breakdown.

Enhancing Vehicle Performance and Safety through Data

The primary benefit of predictive maintenance for vehicles is its ability to significantly enhance both performance and safety. By anticipating potential issues, components can be replaced or repaired before they fail, preventing unexpected breakdowns. This proactive stance ensures that vehicles operate at their optimal condition more consistently, contributing to smoother driving experiences and improved fuel efficiency. Furthermore, preventing sudden failures of critical parts, such as brakes or engine components, directly contributes to road safety, reducing the risk of accidents caused by mechanical malfunctions. This approach underscores a commitment to reliable transport and a safer driving environment.

Predictive Maintenance in Electric Mobility and Sustainability

As the automotive industry transitions towards electric vehicles (EVs) and sustainable practices, predictive maintenance plays an increasingly vital role. EVs, while having fewer moving parts than internal combustion engine vehicles, still rely on complex battery management systems, electric motors, and sophisticated electronics. Predictive maintenance can monitor the health and performance of these critical EV components, optimizing battery life and ensuring efficient operation. By extending the lifespan of vehicles and their components, this strategy aligns with broader sustainability goals, reducing waste and the demand for new manufacturing, thereby supporting a more environmentally conscious approach to mobility.

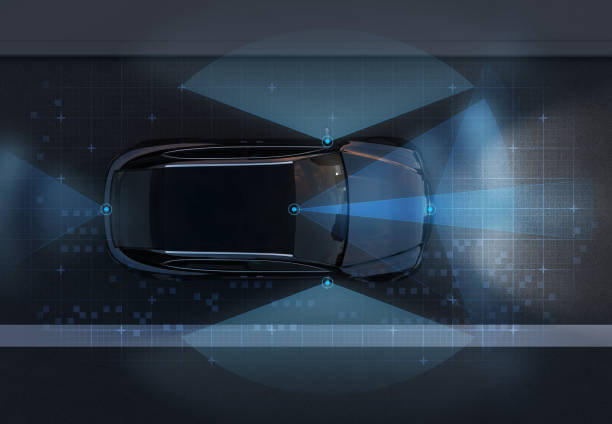

Autonomous Driving and the Future of Transport

The evolution of autonomous vehicles hinges significantly on reliable and continuous operation, making predictive maintenance indispensable for the future of transport. Self-driving cars require components to function flawlessly for safety and operational efficiency. Predictive maintenance systems can monitor the health of sensors, cameras, lidar, radar, and advanced computing units, identifying potential issues before they compromise the vehicle’s autonomous capabilities. This integration ensures the high level of dependability required for autonomous driving to become a widespread and trusted form of mobility, shaping the future of how we travel.

Materials and Design Considerations in Predictive Systems

The effectiveness of predictive maintenance is also closely tied to the materials used in vehicle construction and their original design. Modern automotive design increasingly incorporates durable, lightweight materials that can withstand various stresses, while also being compatible with sensor integration. The choice of materials affects how components wear over time and how accurately sensors can detect changes. Innovations in material science, such as self-healing coatings or advanced composites, can further enhance the data collected by predictive systems, allowing for even more precise prognostics. This synergy between materials, design, and technology is crucial for maximizing vehicle longevity and the accuracy of maintenance predictions.

Cost Implications for Automotive Longevity

Implementing predictive maintenance involves an initial investment in sensor technology, data analytics software, and potentially staff training. However, these upfront costs are often offset by substantial long-term savings. Businesses and individual vehicle owners can experience reduced operational expenses through fewer unexpected breakdowns, lower repair costs due to planned maintenance, and optimized spare parts inventory. The extension of a vehicle’s lifespan also defers the need for new vehicle purchases, representing significant capital savings. While specific costs vary widely depending on the vehicle type, system complexity, and scale of implementation, the economic rationale for adopting predictive maintenance centers on maximizing asset uptime and minimizing unforeseen expenses.

Product/Service | Provider | Cost Estimation —|—|— Data Analytics Software | Various Tech Companies | Varies by features and scale Sensor Integration Kits | Automotive Component Suppliers | Varies by vehicle type and sensor count Predictive Maintenance Platform | Specialized Software Vendors | Subscription-based, varies by fleet size — Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Conclusion

Predictive maintenance represents a transformative approach to automotive care, moving beyond traditional methods to leverage advanced technology for enhanced vehicle longevity, safety, and operational efficiency. By integrating sophisticated sensors and data analytics, this methodology supports sustainable practices, plays a crucial role in the development of autonomous driving, and ultimately contributes to a more reliable and cost-effective transport ecosystem. Its continued evolution will undoubtedly shape the future of how vehicles are maintained and operated worldwide.